It has been a while since I have posted on this blog. I have been busy sourcing antique and vintage fabrics and dyeing katazome textiles. I have also been working on a new website and blog. Please visit our new website for blog posts on antique Japanese textiles and my new indigo dye projects. We also have a shop where you can purchase fabrics and an experiences page where you can learn about upcoming classes and textile tours. Visit the new website at: www.nsomerstextiles.com

Mid 19th Century Katazome with Gourds and Ainu embroidery designs

This Katazome fabric is light and soft and I think the background decorations must have been inspired by the embroidered designs from Ainu robes.

Meiji Era Benibana Dyed Katazome

The two pieces of mid 19th century hand spun and hand woven cotton shown above are dyed using benibana or safflower. This flower in the thistle family is used to dye cotton and silk a range of colors from light pink to deep red. As benibana dyed fabrics age they begin to turn a more brown or rust color like the pieces in this post.

both of the fabrics shown here has been pattered using a katagami, or paper stencil used to apply rice paste to the fabric as a resist before dying. These stencil dyed fabrics are known as katazome.

Antique Japanese Shifu: Paper and Cotton Textile

I found this fabric in Tokyo back in July. at first I thought it was just a piece of indigo dyed cotton, but after picking it up and noticing the texture and light weight I inspected it closer and found that it has a cotton warp and a paper weft. The fabric must date to around the early 20th century.

Above you can clearly see the paper weft threads in one of the ragged ends of the fabric. Below I placed a skein of my handmade paper thread next to the fabric.

While visiting Kyoto I went to Gallery Kei, the gallery had recently exhibited a huge collection of antique paper fabrics. Below is a link to the exhibit at Gallery Kei and some photos of the interior of this beautiful shop. http://gallerykei.jp/event-index.html

Bashofu

Bashofu is a fabric made in Okinawa from the inner fiber of the basho banana plant. The fabric is very hard to come by and I am very lucky to have been able to collect an unused bolt of Bashofu from the first half of the 20th century. The color is a beautiful golden gray and the ikat design of crosses has been beautifully worked. Bashofu is a very labor intensive fabric to produce and each thread is produced by gently knotting the strands of basho fiber resulting in a light textile with lots of texture.

The fiber collected from the central rings of the basho plant must be boiled, scraped, dried, soaked, split, tied, and spun before dying or weaving can take place. Due to the delicate nature of this fiber these processes are all carried out by hand making Bashofu a highly valued textile. Here is a short video that includes the process of making Bashofu: https://youtu.be/Nve0PFa4og4

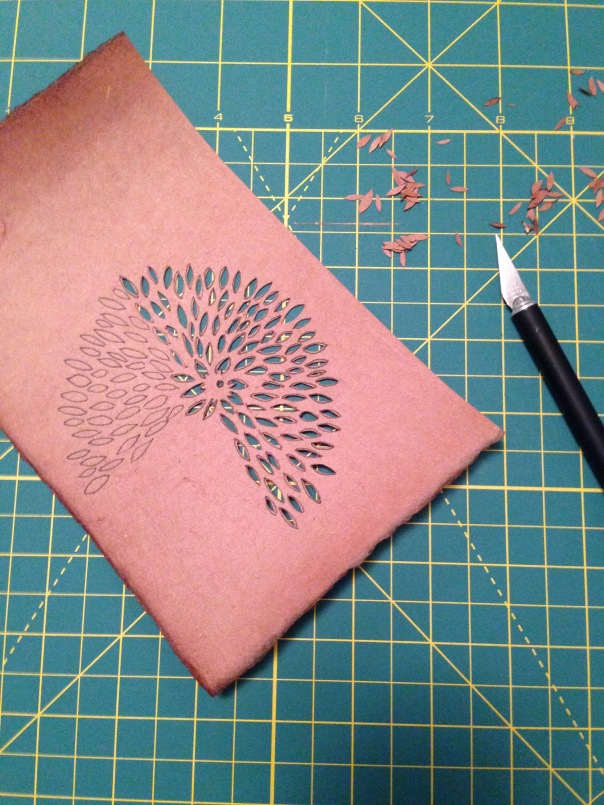

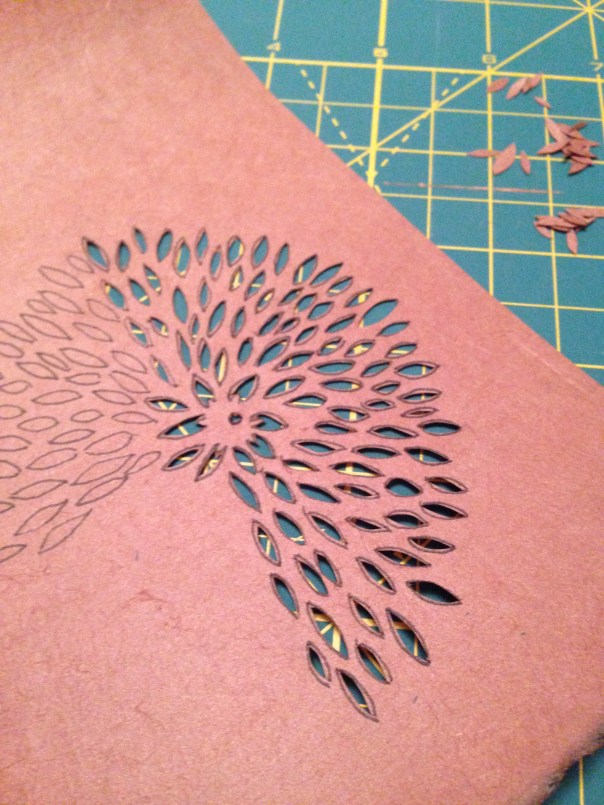

Katazome Experiment

Katazome is a type of fabric that is decorated through the use of paste resist stencil designs. The technique has been used in China and Japan for hundreds of years. I wanted to try the technique, but felt overwhelmed by the large number of supplies needed. This was my short cut experiment in katazome. I began by cutting out a stencil from some small squares of kakishibu treated paper. Kakishibu is a dye made from the fermented juice of green astringent persimmons. It is often used to dye fabric or to waterproof paper. I copied the chrysanthemum and sea holly patterns from some antique fabrics, and I made a simple rice paste glue by cooking glutinous rice flour in hot water for a few minutes. I left the paste to thicken up and cool down in the refrigerator.

The base fabric was dampened with a spray bottle and the stencil was also moistened so that it would lay flat on the damp fabric. I used a small spatula to push the paste through the stencil before removing the stencil and allowing the paste to dry in the sun for about an hour.

After the paste was no longer tacky I dyed some of the fabric pieces with indigo and the rest using kakishibu. The kakishibu dyed fabrics need to be exposed to strong sunlight in order to deepen the color of the dyed fabric. I am pleased with the simplified katazome fabrics that this experiment produced. I wrapped the fabrics up as gifts with some antique Japanese paper from old daifukucho.

Amami Oshima Tsumugi

This summer I spent several weeks in Japan. The first week was spent on the island of Amami where I learned about the fabric traditions of the island. Amami Oshima is located in Kagoshima prefecture and is 2.5 hours by plane from Tokyo. Amami, like Okinawa, was once part of the Ryukyu kingdom and developed its own unique culture and textile tradition.

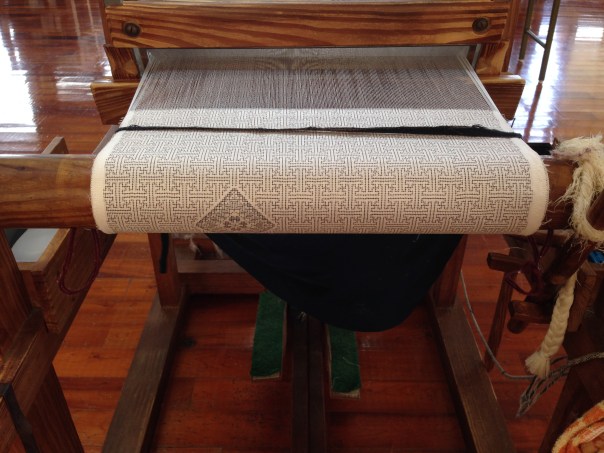

This fabric in the process of being woven is Amami Oshima Tsumugi. It has been woven on Amami for generations and its production is extremely technical and time consuming, but the final product is a strong and durable silk fabric. Many people told me that the fabric can often be worn by three generations being passed from grandmother to daughter to granddaughter.

Amami Oshima Tsumugi is a tabby woven, double ikat fabric. In this technique both the warp and weft threads are dyed before being placed on the loom. The designs are first sketched, the sketch helps the first set of weavers know where to bind the threads so that the final product will create the desired design. This binding is done on a large sturdy loom and the warp and weft threads are sent to the dyers in dense panels of bound silk threads measuring from between 2″x 14″ to 20″x 20″. Subsequently the threads will be dyed before being picked loose from their panels and placed on the loom for their final weaving.

Above you can see a weaver adjusting individual threads with a sturdy needle. The design becomes obscured by the weaving process and needs to be lined up after every inch of weaving.

Below you can see that these looms have two warps. One solid black warp is fixed on the loom by being wound around the warp beam, but the second warp is tied as it needs to be tensioned and adjusted after the weaver completes about 20cm of fabric. Due to the complexity of its weaving it takes a weaver at least 6 months of full time weaving to produce one bolt of fabric. This accounts for its cost of $15,000-$30,000 per bolt.

I also spent several days with the Kanai family at their dye workshop.

Yukihito Kanai stands between two of his friends who also work at the dye shop. Yukihito learned the traditional process of dyeing from his father.

The silk treads are first soaked in a dye made from boiling wood chips from sharimbai, or Japanese hawthorne, which is a native evergreen shrub. After the chips have been soaked and boiled for several days the resulting liquid produces a dark maroon dye.

The thread is washed in the sharimbai dye mixed with lime many times to produce the desired color. When the threads are washed in the iron rich mud of the island a chemical reaction turns the maroon thread a deep lustrous black.

Above you can see the deep black warp threads. Below you can see the panels of bound silk threads which after dying, picking loose, and weaving will produce the desired design. These panels have been dyed with indigo.

Yukihito continues the tradition of dying silk for Amami Oshima Tsumugi, but he also expands the dying and traditional patters to create new products. This tenugui has been screen printed with a traditional pattern representing the village where the Kanai family live. He dyes these with indigo, sharimbai, and mud.

The Kanai family was extremely hospitable and welcomed me to a huge family dinner. A family friend and local fisherman brought amazing fish which was used to make sashimi. Okasan is an exceptional cook, who must have made 20 dishes for dinner. She also used the fish bones to make rich miso soup the next day.

I also had the opportunity to visit a woman who manages and runs a beautiful museum dedicated to Amami Oshima Tsumugi. The museum takes up the top floor of the lovely ocean side Thida Moon Hotel. Her collection is amazing and it is easy to see her passion for teaching others about Amami Oshima Tsumugi. She was a phenomenal host and treated me to an extraordinary dinner made by her and some of the other weavers from the island.

Below is a piece of Amami Oshima Tsumugi I was given by the members of a small weaving workshop I visited.

Silk Worms

This past weekend I visited with my wonderful friend Cassie Dickson. Cassie lives in Western North Carolina and is an exceptional spinner and weaver. She focuses on the weaving of traditional overshot coverlets, but she also grows her own flax for spinning and weaving and raises silk worms each year. This batch of silk worms hatched late and as such Cassie had already collected cocoons and eggs from most of her silkworms. She offered to give me this box of 20 worms to take home. They have happily been eating mulberry leaves from the yard for the last several days

Indigo Plants

A small bed of Japanese Indigo plants I started from seed.

Kami-Ito, Paper Thread Making

Newly spun kami-ito, paper thread, on homemade bamboo bobbins. I made this paper thread from beautiful hand made kozo paper from Korea. I first cut the kozo paper into thin strips leaving both ends attached, then left the paper strips under a damp towel overnight, in the morning I rolled the moist paper on concrete blocks, and then spun the thread using a Japanese spinning wheel. This thread still needs to be boiled or steamed to set the twist. This is my first real attempt at making paper thread.